Standardized Production Base: Laying a Solid Foundation for Contract Manufacturing Quality

The core of contract manufacturing lies in quality and efficiency, with the production base serving as the key pillar. This project boasts a 3,000-square-meter standardized clean production workshop equipped with a full set of automated production equipment. It realizes intelligent control throughout the entire process from raw material processing and formula preparation to finished product packaging, significantly improving production efficiency and product consistency. The workshop employs over 200 professional staff covering R&D, production, quality inspection, logistics, and other key links, forming a mature production and sales closed loop.

Collagen Jelly Factory - High Quality Women Skin Hair Nails Pomegranate

The production base has obtained multiple international authoritative certifications including GMP, HACCP, HALAL, and FDA, along with compliance qualifications such as IQNET and NSF. Its products are exported to many countries and regions around the world, fully complying with the quality standards and safety requirements of the international market. A full-chain quality traceability system is established from raw material selection to finished product delivery, with each batch of products undergoing multiple inspections. This ensures that the products delivered to brand partners are safe and reliable, laying a solid foundation for brand reputation.

Differentiated Product Strength: Building Market Competitive Barriers

This pomegranate collagen jelly has formed multiple advantages in product strength, helping OEM brands quickly seize market share. The core raw material adopts marine collagen peptides with smaller molecular structure and higher absorbability—42 times that of ordinary animal-sourced collagen. It can more effectively nourish the skin, hair, and nails, meeting consumers' beauty and health needs.

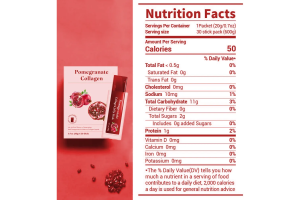

Adhering to the concept of natural purity, the formula contains no artificial flavors or preservatives. It combines real pomegranate ingredients with collagen peptides, offering a fresh and delicious taste in a popular jelly form. The product features independent small packaging of 20g per stick, with 30 sticks per box, making it portable and easy to store, suitable for various scenarios such as commuting and traveling. It has core effects including skin brightening and promoting nail growth, with a wide range of applicable people (excluding only newborns). The large market audience base provides broad room for OEM brands to expand their consumer groups.

Full-Process Service Support: Lowering the Threshold for Brand Cooperation

To facilitate brands' smooth contract manufacturing cooperation, the project provides one-stop OEM/ODM customization services covering the entire process from product R&D to logistics delivery. Brands can flexibly choose services such as formula adjustment, flavor customization (including popular flavors like strawberry), packaging design, and private label customization according to market demand. The minimum order quantity is only 1,000 boxes, adapting to the different cooperation needs of start-up brands and mature brands.

The cooperation policy is flexible and friendly, supporting multiple payment methods including T/T, Western Union, PayPal, and L/C. For the first order, trade assurance services can be used to reduce cooperation risks. Customized orders adopt a model of 30% advance payment plus 70% balance payment before delivery, alleviating the capital pressure on brands. In terms of logistics, it has in-depth cooperation with international couriers such as DHL, UPS, FEDEX, and EMS. For large orders, air or sea shipping is available, and brands can also designate their own freight forwarders to ensure efficient delivery of goods to all parts of the world.

In addition, the platform has an average response time of no more than 24 hours and offers free sample services. A professional team provides one-on-one follow-up throughout the process, comprehensively solving problems encountered by brands in the contract manufacturing process—from pre-consultation and product sampling to later production follow-up and after-sales docking. This allows brands to focus on market operation and promotion.

In the beauty and health contract manufacturing track, this pomegranate collagen jelly offers cost-effective OEM/ODM solutions for global brands with its comprehensive advantages of "high-quality production base + differentiated products + full-process services". Whether it is start-up brands looking to quickly enter the market or mature brands seeking product line expansion, they can reduce entrepreneurial costs and shorten the time-to-market through this cooperation, quickly establishing a foothold in the fiercely competitive market. Choosing a reliable contract manufacturing partner is equivalent to holding the key to tapping into the beauty and health market and sharing the industry's growth dividends together.

By:Global OEMs

By:Global OEMs