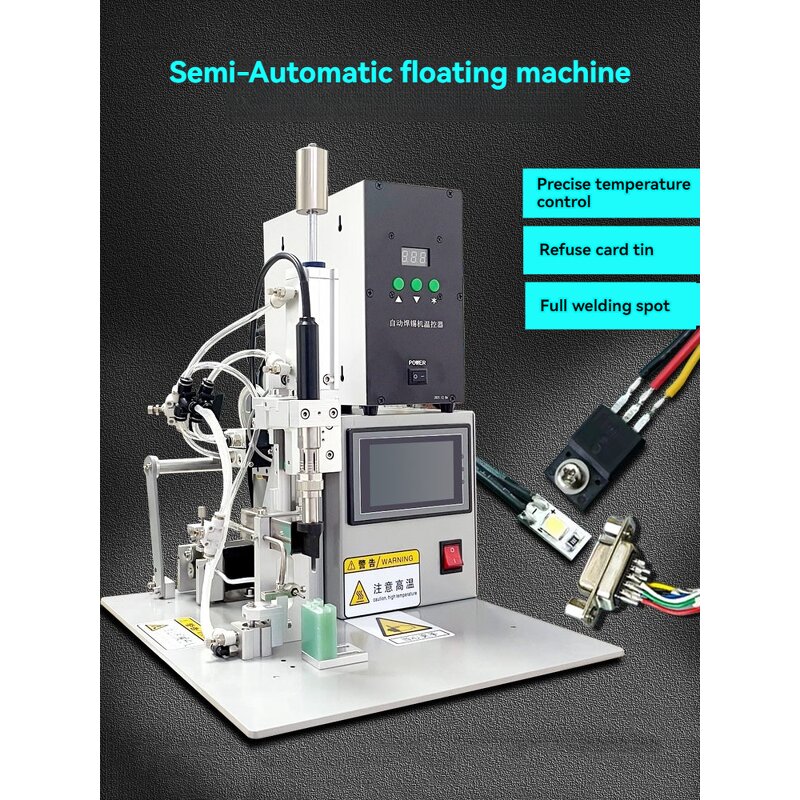

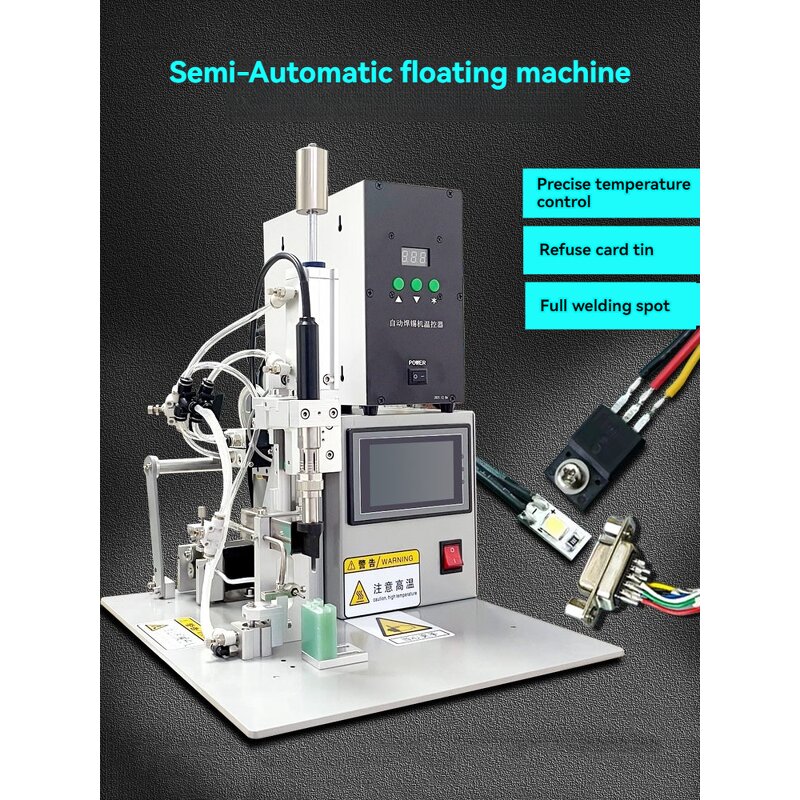

1. Factory Capabilities: Dual Assurance of Technical Expertise and Large-Scale Production

Established in 2018 with a registered capital of US$2.5–5 million, Henan Shanpu Machinery has maintained annual sales in the range of US$2.5–5 million, ranking among the top companies of similar scale. The company employs a professional team of 11–50 people covering R&D, production, and after-sales support, and adheres to an ISO-standardized management system to ensure consistent quality control. Its production base is equipped with high-precision processing equipment, and core components of the soldering machine are manufactured in-house, enabling cost and quality control from the source. Additionally, the factory supports customized OEM services, allowing parameter adjustments (such as voltage compatibility with 220V/110V) and brand labeling, along with free sample testing to meet various market entry standards.

2. Product Features and Competitive Advantages: Precision, Efficiency, and Multi-Scenario Adaptability

-

High-Precision Temperature Control and StabilityThe equipment utilizes 200W high-frequency constant temperature technology, with temperature deviation controlled within ±3°C. It supports solder wire diameters of 0.6–1.4mm, making it suitable for micro-soldering applications such as terminals, switches, LED lights, PCB boards, USB interfaces, and motors. Its semi-automatic operation significantly reduces human error, increasing the soldering pass rate by over 30%.

-

Flexibility and CompatibilityWith compact dimensions of 550×400×350mm and a weight of only 18kg, the machine can be easily integrated into existing production lines and adapted to workshop layouts. It also supports various soldering materials (including lead-free solder wire), complying with European and American environmental standards, thereby helping clients overcome international trade barriers.

-

Cost-Effectiveness AdvantageCompared to fully automatic equipment costing thousands of dollars, this model is priced at only US$800 (with a minimum order quantity of one unit) and consumes as little as 200W of power, resulting in significant long-term energy savings. For small and medium-sized OEM clients, it offers entry-level investment with industrial-grade performance.

3. Service Support: Full-Cycle Empowerment and Rapid Response Mechanisms

-

End-to-End OEM CollaborationThe company provides comprehensive support from design and sample debugging to mass production, supporting brand labeling (OEM/ODM) and custom functional modules (such as digital displays or foot-pedal control) based on client technical documentation.

-

After-Sales and Supply Chain AssuranceProducts come with a one-year warranty, and customer service responds to inquiries within 24 hours. Free samples and product catalogs are available to reduce client decision-making risks. Leveraging Zhengzhou’s logistical advantages, the company’s supply chain network ensures stable delivery times globally.

-

Small-Order-Friendly PolicyFor startups or clients in the R&D phase, Henan Shanpu Machinery accepts small-batch orders (starting from a single unit) and supports multiple payment methods to ease financial pressure.

Conclusion: Win-Win Collaboration to Tap into New Opportunities in Electronic Manufacturing

Henan Shanpu Machinery’s 200W Semi-Automatic Soldering Machine is not only a cost-effective and reliable tool for OEM manufacturing but also empowers brand owners to quickly seize market opportunities through flexible services and technical support. Whether expanding into smart homes, automotive electronics, or new energy sectors, this equipment can serve as a core enabler for supply chain optimization. As global electronics supply chains continue to integrate, partners with technical expertise and service flexibility will lead industry transformation.

By:Global OEMs

By:Global OEMs