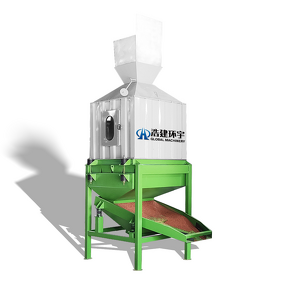

The rotary flat-die feed pellet mill is an improved version of the ordinary flat-die pellet mill, specifically designed for small and medium-scale feed processing and organic fertilizer granulation. Its core innovation lies in the rotating flat die and fixed pressure roller working unit.

After mixing, the powdered raw materials are fed to the pressure roller area by the rotating flat die. Under pressure, the material passes through the die holes to form cylindrical pellets. This process ensures more even pressure distribution, resulting in a high pellet formation rate, uniform density, and reduced breakage.

This equipment can process various materials such as straw, soybean meal, grains, and bran. It features a compact structure, simple operation, and low maintenance costs. It is suitable for small and medium-sized farms, feed processing workshops, and organic fertilizer production facilities, making it an ideal choice for improving feed utilization and reducing breeding and processing costs.