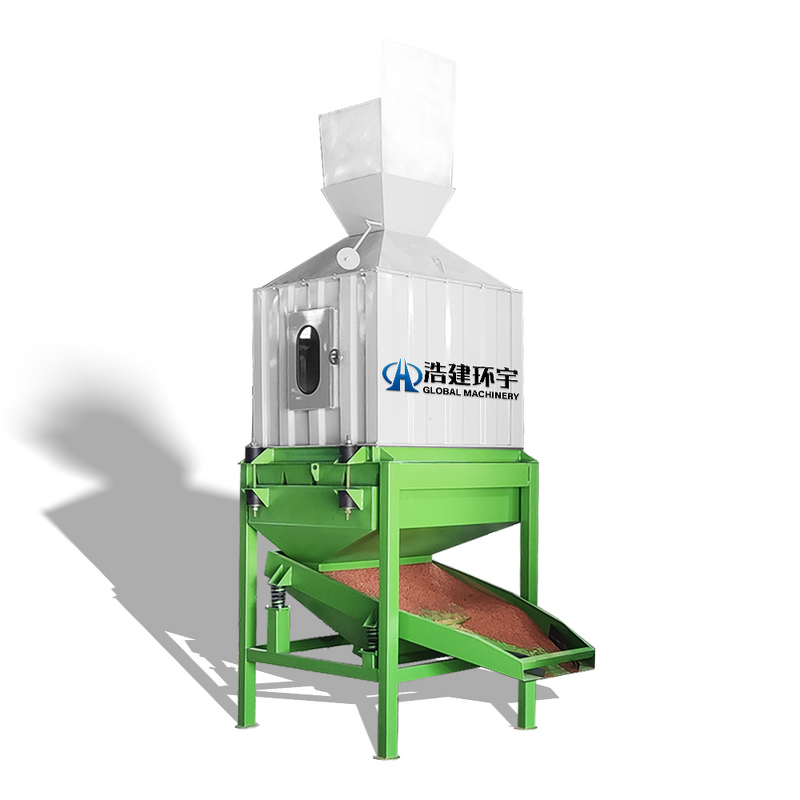

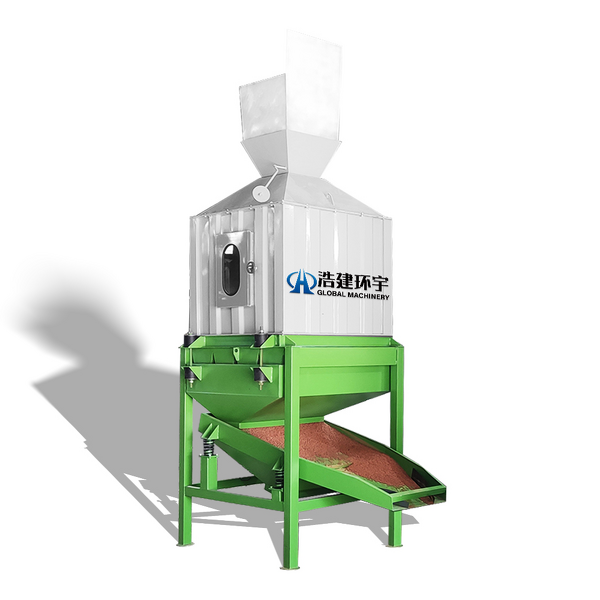

The octagonal counter-current cooling system is the core cooling equipment in feed processing production lines, specifically designed for high-temperature, high-humidity feed pellets produced by pellet mills. Its core structure consists of an octagonal cooling chamber, an air guiding system, and a discharge mechanism. The working principle is "counter-current heat exchange + uniform airflow without dead zones": hot pellets at 70-90°C flow from top to bottom, while cold air vertically penetrates the material layer from the bottom upwards, first contacting the cooler material and then gradually exchanging heat with the hotter material. The octagonal structure prevents cooling blind spots, effectively cooling the pellets to room temperature + 3-5°C and reducing moisture content to a safe standard of ≤12.5%, preventing pellet cracking or mold growth.

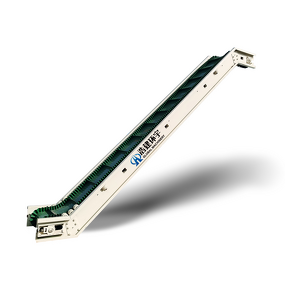

This system is suitable for continuous production scenarios in feed mills and should be installed after the pellet mill, operating in a well-ventilated workshop with sufficient space. It can be integrated with screening and dust removal equipment, ensuring pellet hardness and storage stability while reducing energy consumption. It is an indispensable supporting equipment in large-scale feed processing.