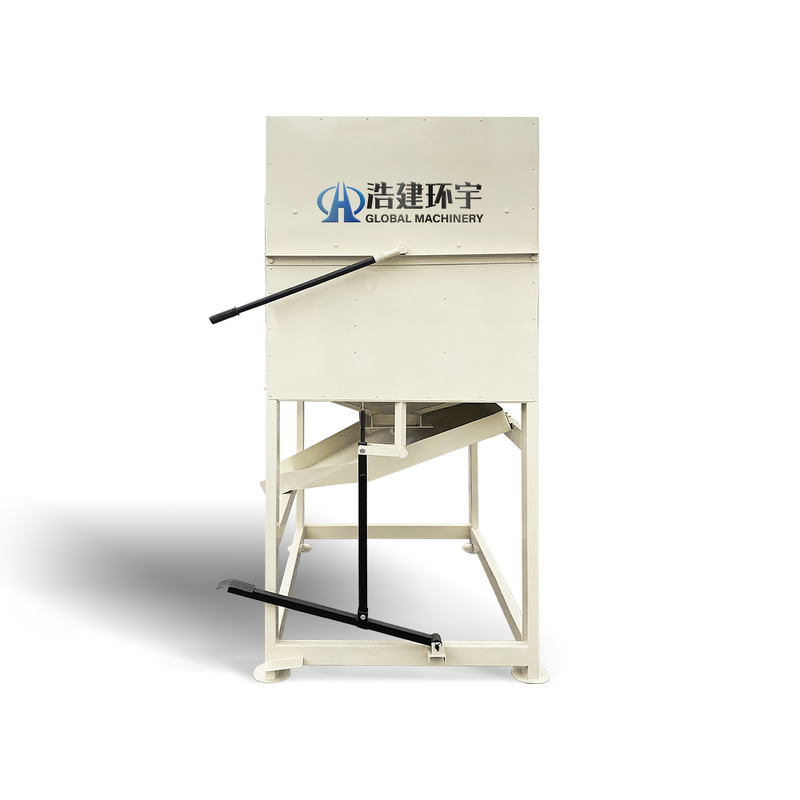

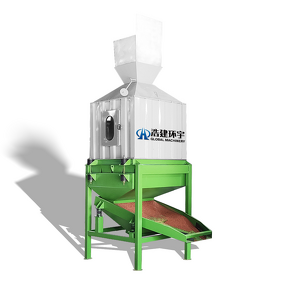

The air-cooled vibrating dust removal equipment is a specialized dust control device for feed processing production lines, suitable for dust purification in key stages such as pellet pressing, raw material crushing, and finished product screening.

The core structure consists of a vibrating screen body, an air-cooling system, a dust collection device, and an electrical control system. The working principle is based on a dual-effect synergy: the vibrating screen body vibrates at high frequency, separating feed particles from attached dust such as grains, soybean meal, and bran; the air-cooling system simultaneously delivers airflow, accelerating dust dispersion and guiding it to the dust collection device, achieving gas-solid separation. This reduces dust dispersion and prevents raw material waste.

This equipment can be integrated with flat die/ring die pellet mills, crushers, etc., and is suitable for feed processing workshops with good ventilation and ample space. It effectively controls dust pollution, prevents cross-contamination of feed raw materials, and ensures a clean production environment and the health of operators. It is a low-cost, easy-maintenance dust removal solution for feed processing.